Our Products

Lead Anodes

Whether extruded or hand-cast in our wide range of alloys and configurations, each of our anodes go through the same process to produce a fine-grain structure essential for even plate-out and maximum throwing. We manufacture lead anodes for a range of applications:

- Hard Chrome Plating

- Decorative Chrome Plating Anodes

- Anodizing

- Tin & Solder Electroplating

- Galvanizing

- Metallizing

- Lead Plating Anodes

- Basket Anodes

- Tin Lead Anodes

Alloys

Find below a list of the raw metals that we alloy with to produce any configuration you require.

- Tin (Sn): Complies to ASTM B339 – Grade “A” Tin.

- Lead (Pb): Complies with ASTM B29 – Corroding Grade Lead.

- Antimony (Sb): Complies with ASTM B237 – Grade “B” Antimony.

- Cadmium (Cd): Complies to ASTM B440

- We also produce alloys with additions of Silver (Ag), Bismuth (Bi), and Aluminum (Al).

Anode Categories

Tap a category and scroll down to see your choice.

Whether extruded or hand-cast in our wide range of alloys and configurations, each of our anodes go through the same process to produce a fine grain structure essential for even plate-out and maximum throwing.

We also produce Lead anodes with cores such as copper, milled steel, and aluminum to name a few. They are either screwed or threaded into the hook, and plugged at the bottom.

All our Lead Alloyed Anodes are available with either Cast Bronze or Copper Hooks, which are cast into nobbins and lead-burned onto the anode stock. (All nobbin & burning bar used in homogenous bonding are of the same alloy as the anode stock).

Tin Anodes are supplied drilled with a 3/8″ Diameter hole and tapped (16 thread) to 1-1/4″ deep.

On Mobile? Swipe to Scroll ← →

Standard Extruded Configurations

| Sample Picture | Configuration Name | Dimensions | Metal |

|---|---|---|---|

|

ROUND | 1/8″ – 4″ Dia Various Lengths |

Tin Lead Tin/Lead Alloys |

|

SQUARE | 1/8″ x 1/8″ – 3″ x 3″ Various Lengths |

Tin Lead Tin/Lead Alloys |

|

RECTANGLE | 1/8″ – 3″ Max. Width = 5″ Various Lengths |

Tin Lead Tin/Lead Alloys |

|

“D” STYLE | 2″ x 3″ Various Lengths |

Tin Tin/Lead Alloys |

|

OVAL | 2″ x 3″ Various Lengths |

Tin Tin/Lead Alloys |

|

ELLIPTICAL | 2″ x 3″ Various Lengths |

Tin Tin/Lead Alloys |

|

ROSETTE | 1-1/2″ & 2″ OD Various Lengths |

Tin Lead Tin/Lead Alloys |

|

12 STAR | 2″ ID, 3″ OD Various Lengths |

Tin Lead Tin/Lead Alloys |

|

SAWTOOTH | 1-1/4″ x 4″ Various Lengths |

Lead Tin/Lead Alloys |

|

RIBBED | 3/4″ x 3″ Various Lengths |

Lead Tin/Lead Alloys |

|

ZIGZAG | 3/16″ x 3″ with 7/16″ Centre Various Lengths |

Lead Tin/Lead Alloys |

This is a list of our most common bronze hooks. Copper hooks are available upon request.

- All hooks can be Plastisol covered or Lead covered, just let us know in advance.

- Hooks come standard as “C” Bronze

- We’ll also customize your copper hook if required

On Mobile? Swipe to Scroll ← →

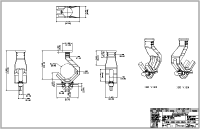

| Sample Picture | Hook Number & Style |

Dimensions | Max Buss Bar Size |

Technical Drawing | |

|---|---|---|---|---|---|

|

#1 Single Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 3-1/2″ Knife Edge: 1/2″ Thick |

1.5″ Square 2.0″ Dia. Round |

See Tech Drawing |

|

|

#2 Single Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 3-1/2″ Knife Edge: 5/8″ Thick |

1.5″ Square 2.0″ Dia. Round |

See Tech Drawing |

|

|

#3 Single Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 3-1/2″ Knife Edge: 3/4″ Thick |

1.5″ Square 2.0″ Dia. Round |

See Tech Drawing |

|

|

#7 Double Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 3-1/2″ Knife Edge: 5/8″ Thick |

1.5″ Square 1.75″ Dia. Round |

See Tech Drawing |

|

|

#8 Double Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 4-1/2″ Knife Edge: 5/8″ Thick |

2.0″ Square 2.5″ Dia. Round |

See Tech Drawing |

|

|

#9 Double Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 8-1/2″ Knife Edge: 1/2″ Thick |

2.0″ Square 2.5″ Dia. Round |

See Tech Drawing |

|

|

#10 Double Knife Edge |

From Top of Conductor Bar to Anode Shoulder: 9-1/2″ Knife Edge: 1/2″ Thick |

4.0″ Square 4.0″ Dia. Round |

See Tech Drawing |

|

|

#10 Heavy Amperage |

From Top of Conductor Bar to Anode Shoulder: 9-1/2″ Knife Edge: 1″ Thick |

1.5″ Square 2.0″ Dia. Round |

See Tech Drawing |

|

We want to make sure you get the best bang for your money – a custom conforming or non-conforming grid anode can save you thousands of dollars and man-hours. Instead of using multiple different anodes to apply the chrome evenly and efficiently, a single custom conforming anode can apply an even distribution all at once.

We can integrate any size copper leads into your anode, in any formation for connecting to your buss bar.

Pleasure Craft Anodes

Reliance Sacrificial Anodes from Alchemy Extrusions Inc., are made to meet or exceed military specifications, including MIL-A-18001, the accepted authority used by governments of both Canada and the USA. Cathodic Protection of Commercial Vessels, Piers, Dry docks, Retaining Walls, Off-Shore Drilling Platforms, Pleasurecraft & Oceanographic Equipment.